Denounce with righteous indignation and dislike men who are beguiled and demoralized by the charms pleasure moment so blinded desire that they cannot foresee the pain and trouble.

Read MoreHigh Recovery & Extended Membrane Life

Do you happen to be experiencing any of the following issues? If so, it's imperative to recognize their magnitude as they can pose significant problems.

Here's an illuminating insight into the primary contributing factors which cause fouling of the RO membranes.

- Presence of organics / Sticky polymeric precipitates in feed water stream

- Other inorganic precipitates

- Residual COD & other micro-pollutants being fed to RO

Excessive chemicals‘ dosage increases the ORP and frequent CIP reduces the life of the membranes

Excess flocculating polymers from prior treatment

Cationic polymers when mixed with anionic anti-scale chemicals

TSS / Suspended particles not pre-filtered

Presence of silt, clay, silica / sand as suspended particles

High mineral content- Calcium and magnesium carbonates, bicarbonates and sulfates causing increased hardness in the feed water

Fats, Oil & Grease traces

Iron and rust with other metallic impurities

Odour and Colour in the feed effluent

Presence of live micro-organisms- Bacteria, pathogens, viruses etc.

The present industry approaches to address and mitigate fouling in RO (reverse osmosis) membranes are worth examining.

– Media Filtration (MGF, DMF, PSF / ACF )

– Cartridge Filtration (MCF)

– Micro Filtration (MF), Nanofiltration (NF) and Ultrafiltration (UF)

These methods come with certain limitations as these cannot completely remove

micro-organisms, is less effective with dissolved organics and need frequent

maintenance.

The Solution

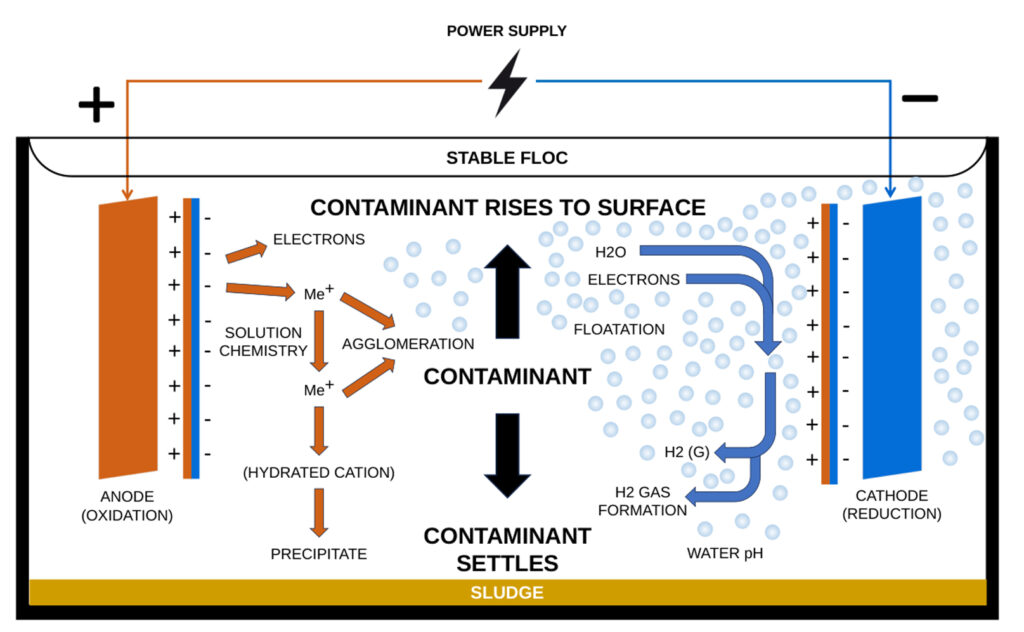

.Futura EHO process- By means of oxidation using electricity, we turn the stable colloids into unstable colloidal particles, partially or completely neutralizing the charge around the particle surface allowing them to come together (Van der Waals forces) and agglomerate into larger particles.

This oxidation process causes precipitation reactions and releases the hydroxyl ions which attach to the surface of the particles causing them to agglomerate into larger particles and precipitate. Now these larger particles can settle as well as can be filtered before feeding to the RO.

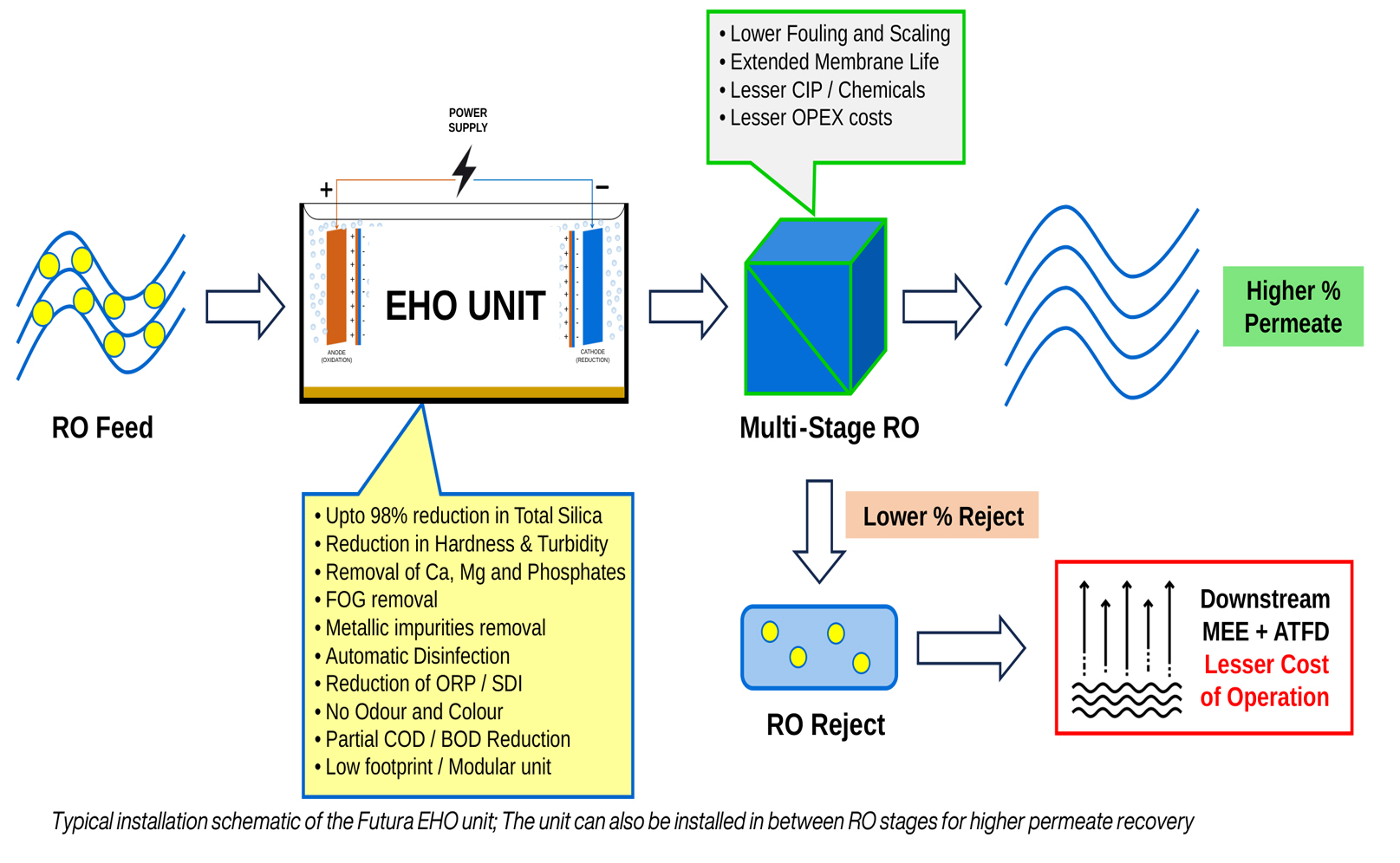

The EHO process is a water treatment technique designed to mitigate scaling & biofouling in reverse osmosis (RO) membranes. Its mechanism of action involves reducing the levels of organic and inorganic contaminants present in the feedwater. This innovative approach is incredibly cost-effective and has proven to be an efficient control technique for RO fouling. The benefits of utilizing the EHO process are evident as it results in considerable savings in the operating costs of downstream MEE and ATFD, making it an excellent return on investment.

Our EHO unit modules have an ultra-low footprint requirement, ranging from 12 sq.m for 50 KLD installations to 24 sq.m for 600 KLD installations. Futura EHO Process- Increase RO Recovery In summary, Futura EHO process can be a valuable pre-treatment method for RO systems to reduce scaling & biofouling by oxidizing & removing contaminants and microorganisms, improving water quality, and decreasing the reliance on chemical treatments. Its application should be carefully evaluated and optimized for each specific water treatment scenario to achieve the desired results.